A Journey from Humble Beginnings to Industry Leadership

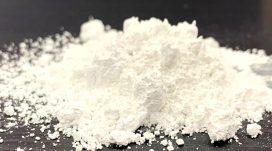

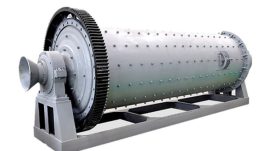

At Khawaja Mineral Industries, we take pride in our journey from humble beginnings to being a leading provider of industrial minerals. In the year 1999, Khawaja Mineral Industries (Pvt) Ltd embarked on a transformative journey, starting with a single Ball Mill and a modest production of 45 microns(Top cut) calcium carbonate. Over the years, responding to the escalating demand for Talc & Clay, KMI evolved and expanded its capabilities.

Forging a Legacy: The Milestones of KMI

1999

Pioneering Inauguration

Embarking on a pioneering journey, KMI inaugurated its initial Ball Mill Grinding Plant, marking the genesis of a legacy in industrial minerals processing.

2002

Setting New Standards

Our commitment to excellence was evident as we achieved a remarkable fineness of up to 45 microns, setting a new standard in industrial minerals processing.

2004

Significant Expansion

A significant expansion unfolded with the installation of the second Ball Mill Plant, coupled with an impressive improvement in fineness, reaching up to 20 microns.

2006

Groundbreaking Achievement with China Clay

A groundbreaking achievement as KMI introduced China Clay with a fineness of up to 10 microns, a milestone recognized as the first of its kind in Pakistan.

2007

Notable Accomplishments

A year of notable accomplishments—from attaining ISO 9001:2000 certification to the addition of our third Ball Mill Plant, enhancing capabilities and achieving fineness up to 8 microns.

2008

Ushering in a New Era of Technology

Ushering in a new era of technology with the introduction of the first Roller Plant Mill equipped with a turbine classifier, reinforcing our commitment to cutting-edge solutions.

2009

Enhanced Delivery Services

Enhanced delivery services with the introduction of new vehicles optimized and expedited the transportation process.

2012

Strategic Move into High-End Talc Production

A strategic move as we commenced the production of high-end Talc with an acid solubility of less than 2%, setting a new benchmark in quality.

2013

Expansion and Innovation

A year of expansion and innovation with the addition of the second Roller Mill Plant and the installation of the Imported Continuous Coating Plant, marking a pivotal moment in our journey.

2015

Advancements in Facility Capabilities

Advancements with the incorporation of an Air Jet Mill and the cutting-edge Malvern Mastersizer 3000, enhancing capabilities and precision in particle size analysis.

2017

Soaring Growth and Certification

Our growth soared with the integration of a Roller Mill for production improvement, Magma Therm Furnaces for quality enhancement, and achieving ISO 9001:2015 certification, fortifying our commitment to quality and innovation.

2018

Continued Expansion

The expansion continued with the installation of another Roller Mill and a fleet of efficient transport vehicles, solidifying our position in the industry.

2019

ACM Mill Acquisition

Advancing into 2019, the acquisition of an ACM Mill underscored our dedication to technological prowess, enriching production capabilities and bolstering our standing as a forward-thinking entity.

2021

Milestone in Sustainability

A milestone marked with the incorporation of additional vehicles and a 100KW solar system, a sustainable stride towards minimizing our environmental footprint and embracing eco-friendly practices.

2022

Augmentation with Roller Mill

The year 2022 witnessed a significant augmentation with the introduction of Roller Mill, amplifying our production efficiency and reinforcing our commitment to staying at the forefront of cutting-edge technology.

2023

Commitment to Sustainability Continues

Continuing our trajectory of sustainability and innovation, 2023 saw the integration of a powerful 275KW solar system, aligning our operations with eco-conscious principles and contributing to a greener future.